Determination of material properties

We determine technical parameters of metallic, ceramic and polymer materials according to standards (DIN, ISO, ASTM etc.) or customer specifications:

- Hardness and hardness curve

- modulus of elasticity, yield/elongation limit, tensile strength, elongation at break

- Flow curves

- Residual stress test

- Impact energy (temperature-dependent)

- Layer thickness (non-destructive/destructive)

- Dynamic strength characteristics

- Determination of the Wöhler line

- Vibration test

Examples of processed orders

Tensile tests on

- Drawn and annealed 60 µm wires made of nickel-based and iridium alloys.

- stainless steel samples produced by selective laser melting (SLM) or metal injection moulding (MIM)

- Thin spring steel and electrical steel sheets

- (aged) polymer standard bars (between RT and 200°C)

- polymer safety nets (fall protection for construction sites)

- high strength bolts

- anchor bolts

- standard tensile specimens

- pre-material for cold forming and tubes

Compression and bending pressure test on

- Ceramic plates

- Camshafts, hollow shafts

- GRP and carbon composite components

Puncture, tear, tear-out and pull-off tests on

- Espresso capsules

- Textile fabrics

- Wall anchors

- Needle bearing fixings (between RT and 200°C)

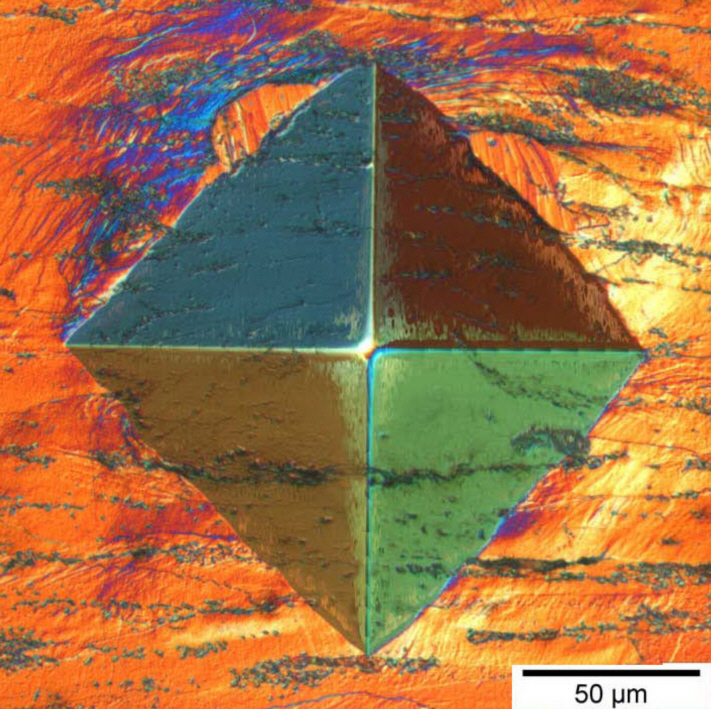

Hardness curves on

- Gear wheels

- screws

- Case hardened ball hubs

Pendulum impact and notched bar impact tests on

- Structural steels

- Tool steels

- Fastening screws for indexable inserts

Dr.-Ing. Kerstin Kern

IMP Institut für Mikrotechnik und Photonik Projektleiterin und Fachverantwortliche Werkstoffprüfung

+41 58 257 34 08 kerstin.kern@ost.ch

Jan Allaart

IMP Institut für Mikrotechnik und Photonik Experte für Schadensanalyse

+41 58 257 33 75 jan.allaart@ost.ch