Research project

Dynamic marking of injection moulded parts

The standard method for the unique identification of injection moulded products is currently the use of downstream systems (e.g. adhesive labelling, laser engraving or inkjet printing), which require additional space in the production facility and a separate process step.

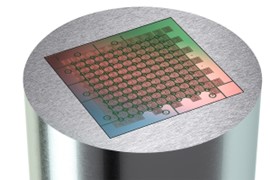

The new marking variant developed in this project is based on mould inserts that use matriq AG›s patented «DynamicMold» (DM) technology to provide a new type of tracking and identification solution for injection-moulded plastic parts. The mould inserts provide a unique and constantly changing DataMatrix code, which is melted onto each manufactured plastic part during the moulding process.

Partner: